By akademiotoelektronik, 24/06/2022

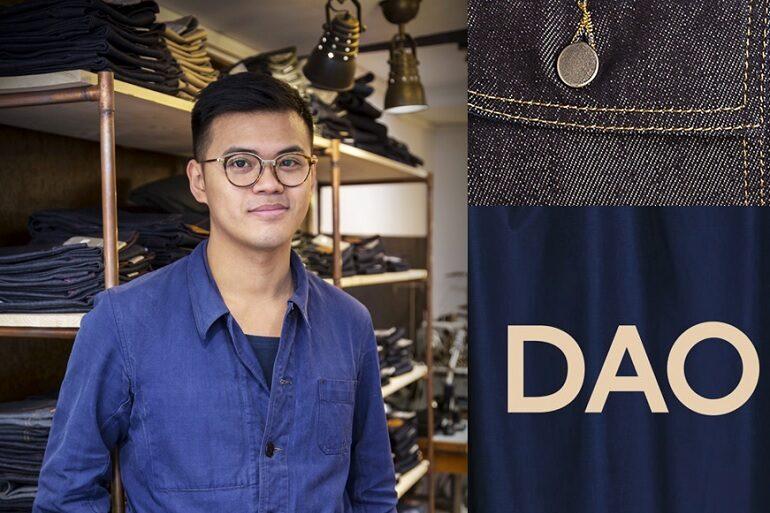

Interview: Davy Dao, Dao leader

Did you dream of reinvented jeans made in France?Dao has taken up the challenge!The fashion brand was indeed the first to offer Denim Lin, 100% cultivated and manufactured flax jeans made on the territory.

Founder of the brand in 2012, Davy Dao made her dreams of teenager a reality.But if he has always wanted to create a clothing brand, his confrontation with the reality of the fashion sector in Ho Chi Minh Ville, Viet-Nam made him aware of the need to "make differently", especially jeans.Located near Nancy, DAO therefore offers quality, timeless and durable clothes, with the most ethical and ecological manufacturing possible.

DAO is an entrepreneurial project on a human scale, nourished by creativity, innovation and pragmatism.At the border between crafts and industry, the brand is betting on natural materials, including organic cotton.If its denim Lin made it known to a wider audience, it also offers pants of the male and female ready-to-wear collections of French quality, or even selvedge jeans in Japanese canvas tingednatural indigo.The brand mainly pays particular attention to the information and advice given to customers, in stores or on the Internet, whether on manufacturing but also on how to combine clothing on a daily basis until its maintenance.

On the front of the scene of the new French and transparent fashion thanks to its Denim Lin released in 2018, Davy Dao takes advantage of this recognition of its know-how to continue the development of the brand.Between risk -taking and opportunities, tradition and modernity, he explains the path traveled and the reasons why 2021 has finally become the year of DAO's consolidation.

In a few words, could you explain to us what a "fabricated jeans" is at DAO?

As a sharing, this means first of all that we act on the manufacturing aspect, that is to say on the transformation of the matter that we receive, but there is also a desire to think upstream of the process, inDeveloping our own denim tissues.

The value chains of the fashion sector remain, despite recent efforts, still too opaque.With hindsight and experience acquired in recent years, fabricating otherwise means being transparent about our way of doing things, from raw material to washing, all the value chain of clothing with a real ethical dimension. We must be inMeasure to communicate with the teams that make our clothes, but also to manage differently, to be more attentive to employees.This management aims to be more collaborative, more horizontal, and at Dao each in his say.

It has also become essential to popularize and explain the technical terms inherent in our manufacturing processes, to make this knowledge accessible to the greatest number and facilitate the understanding of our profession, the specificity of our clothes.Fabricating jeans otherwise is trying to take a step aspect on all aspects of our profession, choose a new path in terms of sourcing, choice of partner weavers, ennoblement processes, to washing andCommercial network.

You operate on the jeans sector, globalized and very competitive.Why launch such a challenge on a mature market?

I knew very early on that I wanted to create clothes.I come from a family of eight children, and it was only at fourteen years old that I was able, for the first time, to buy my first Jean, the first that I would not have recovered from my brothers andRabied, a real symbol ... nobody has worn it before me!My parents did not want me to embark on the fashion adventure, however I had the certainty of wanting to do it.Of Vietnamese and born origin in France, I spent a year in Asia during which I was able to discover part of my job there.Unfortunately, I was able to become aware with jeans hid the underside of globalization, workshops without law without protection of employees and difficult work environments.

I wanted to deconstruct the myth that it is necessary to have the other side of the world made to be profitable.I believe in the possibility of producing short circuit, and as we do today, to employ fourteen people mobilized around a common project.It is much simpler for me to explain my work, to guarantee the safety and transparency of my process and to be in accordance with my values by working in France rather than being a leader with suppliers to the'Another end of the world.

For the little anecdote, I had the chance to meet one of the co -founders of the clothing brand Bill Tornado a few years ago.He told me a sentence very fair to do this job: "You have to be a believer, beyond believing in God, you have to believe in yourself".This is a sentence that I transmit very often during my interventions with high school students and students who wonder about what you need to know before embarking on the entrepreneurial adventure.

It is sometimes expressed the fact that "there is no chance, only meetings".Is it your feeling too?

It is true that over time, we realize that the meetings are ultimately provoked by our careers!I had the chance to meet extraordinary people in the field of machines we need to make our jeans, including for example François, the most recognized man in France for his know-how on the Reece buttonhole machines.I was lucky to chat with him on his job.He gave me advice for the development of DAO, to go see the right people, the suppliers with whom to build a relationship both human and commercial.François recently left us and I cannot pay tribute to him for all that he has brought us, to me personally, to my business, and I think of our entire sector.

You rely on a network of partners, in particular weavers, but also washing specialists for example.How is this network built over time?It is often difficult for young creators to have very small series made, what were the difficulties and solutions for DAO?

With the young experience I can have today, I understand better the constraints inherent in the weaver profession for example.This profession rich in know-how is unfortunately sometimes a little "ungrateful" since it requires millions of euros in investments, with strong market constraints, especially on the minimum volumes to be produced to be profitable.

To weave links, it is a sector where resentment has no place!It is indeed useless and counterproductive, since the constraints of some can adapt to those of others, and agreements end up being signed.Beyond the figures, young entrepreneurs and fashion designers must be realistic, and realize the economic and industrial reality of their suppliers and partners.A negative response indeed reflects not the refusal of manufacturers to work with you, but simply a practical impossibility of responding to your request.

For my part, I launched the DAO brand by making myself. Then, I found intermediate solutions, thanks to secondary and alternative networks rather than the most demanded those located in the capital. For young creators, one of the pragmatic ways to explore to get started is to work with textile recycleries, with unused tissue rolls, to make the first prototypes. It is by exchanging with those responsible for these recycleries that it is possible to know more about their "suppliers", to know more about the players in the sector and target potential contacts. Finally, two points are extremely important to get started: being able to prove that you are able to make a prototype, because a drawing is not enough, and showing real financial realism by presenting a sales provisional. In short, know where we are going and why we are going! Any idea is good if it is well presented, supported, benchmark. This need to open up and be inspired by the world, understand your market, adopt the point of view of potential customers.

Regarding the relationship with the weavers, when launching my activity I simply started working with manufacturers who agreed to work with me!They were then Japanese, Portuguese, Germans, Spanish ... but not French.In the countries cited, many manufacturers have in fact integrated market developments for several years.In France, there are still too few weavers with "stock service" fabrics, that is to say to order on a single reference one meter, or eighty meters depending on the need, in order toTo perpetuate a minimum a collection.

It seems important to me that each stakeholder wants to take a minimum risk.We wanted to work for a long time with Cédric Plumey who was embarking on the adventure with METIS manufacture, and our first order of almost two thousand meters of fabric allowed him to really accompany his weaving activity, by making it known, by communicating onour collaboration.In the same way, the weavers should agree to take the risk of supporting certain creators on smaller series sometimes.

It is not easy to reinvent the basics of our dresses and to differentiate yourself.Linen denim is your flagship innovation, how was this project born?

In 2016, strikes took place in France, especially in transport, ports and airports, with the consequence of my cargoes of fabrics from Japan blocked in the port of Le Havre

I found myself faced with a crucial question: if in the future the blockage continues or if only the price of freight explodes, what solutions can I have to have the material available in a shorter circuit?By doing some research, I discovered that we were, in Europe, the main world producers of flax, which I didn't know until then.This is a real school case!

This innovative project was therefore born out of an intuition, almost with an instinctive character.After almost two years of research and prototyping, we launched our jeans in linen in 2018. I do not know if it is a revolution of jeans, but I took this risk, at an instant t, ofTest linen as the basis of a denim canvas, which had not yet been done.We have innovated step by step, thanks to the experiment.We also took advantage of a marketing strategy orchestrated by CELC at this time.On the argument side, everything was already written, described, but it was necessary to bring this information on flax as close as possible to the consumer to give birth to the desire to buy this jeans.And there is a real interest around this material, confirmed by the projects of other French jeans manufacturers who have also launched into this wake.

Do you have any desires to go and test other more "exotic" materials as you have been able to do with hot air canvas?

In this case it was really an opportunity, given as part of our partnership with the World Air Ballon in Lorraine.It was an opportunity to show our know-how.We made pants from this hot air balloon canvas, and even if in my opinion we should have revalued these fabric falls otherwise, more relevantly, it was an interesting project to get out of our daily life, to push the limits andfeed reflections within the workshop.This opens the field of possibilities in the rest of our product ranges.

I think there is something to create from these particular textiles when they are at the end of the cycle, but rather in the line of companies like Rains or Stutterheim, or according to the heritage of Freitag which through hisAccessory range has managed to make the used truck tarpaulin a brand example in the circular economy category.But to develop and perpetuate a responsible brand, with ecological and ethical values is a long -term project, which requires not to spare too much, so it is not my priority.

You only work with natural materials, especially organic cotton.Why does this choice rather to continue with recycled cotton for example?

We have indeed launched a small recycled cotton range a few years ago, in particular socks, born out of opportunities and proposals from our knitter.It is in this same approach that we are always working more on alternative materials, and exchanges with new weavers' partners allow us to work on organic cotton.This can even be worked in a mixture with recycled cotton, flax, or even hemp.The door remains open on a possible use of recycled polyester, only on certain product ranges if it seemed necessary to us.The objective remains to proscribe, ultimately, all subjects from crude oil.Within four years, we want to get rid of any trace of pure plastic in the manufacture and marketing of our clothes.

Traceability, in particular materials, is one of the major challenges to be met for the textile-accommodation sector, how do you apprehend it at DAO?

Setting up our products otherwise involves checking, and not just displaying labels. The relationship we have with our suppliers is based on trust, however it seems essential to know their workshops, their employees, the working conditions on site. Until now we have been able to visit our Spanish, Greek and Turkish spinners/weavers, directly in the geographic areas where our organic cotton is cultivated. The period of health crisis has unfortunately slowed down our audit projects, but our desire is clearly to meet all our partners, at the origin of the subjects we work. This is what we are already doing with our French partners. Perhaps we will have to systematize our visits to the spinners in the near future. After ensuring French manufacturing and short circuit sourcing around linen, we will have to answer the questions we ask ourselves on other subjects.

There is a young and small cotton production in the southwest in France, which must be greet.This slightly crazy project launched on the initiative of the young brand Jean Fil is about to transform the essay of "all traceable" on the territory.We are not customers but we exchange a lot with the founders, and wish them the expected commercial success.

What about elastane in all of this?

We seek to do without the years to come, but the alternatives are difficult to find.However, there is a trend, against the current idea that the stretch effect would be necessary when buying pants.In contact with our customers in stores, we realized that consumers, and in particular women, are looking for fewer and fewer elastic jeans.The trend is rather for pants with a certain outfit, which hold the body, which hug the size, a little in the idea of the Levi's 501 of the time. These cuts without elastane are adapted to our know-how, and we are looking forSo also to satisfy these needs expressed in particular with the boom of vintage and the second hand.

You have a new modernized workshop recently.Today's crafts should know how to go to this CAP to meet demand?

If we have been thinking about it for some time, things did not necessarily go very quickly on this point of the transformation of the workshop.But the pandemic struck last year, and any crisis generating opportunities, we seized that of making masks.The department of Meurthe and Moselle asked us for this task with regard to our confection.But at the time we were barely three people in the workshop!The community therefore helped us create a whole production line from almost nothing.I imagined production lines, and with an enlarged team we were able to make nearly 900,000 masks in the space of two months and ten days.

My Roman partner did not want to respond to the solicitation, faced with the difficulties announced and for fear of not being able to deliver these masks.But by exchanging together, it was obvious that the very DNA of DAO is based on the short circuit, local manufacturing, the agility of a small team, the adaptability of French manufacturers.If there was a moment to show it, then it was this one.Sometimes you have to know how to take the turning point as risky as it is.The initial demand was 250,000 masks, an already very large volume for our size but it quickly increased to meet the needs.We temporarily recruited staff, and 95 people joined us, and worked tirelessly, with two night teams and three day teams.

This is how we learned to become industrialists and to make the company grow.We were three, we are fourteen today.The equipment acquired to make masks has been designed to be reused in our traditional pants manufacturing activity.So we opened our new workshop last year, and cruising speed is now reached.

French manufacturing is supposed to provide jobs, guarantee shorter manufacturing times, and more responsible, more ecological, more social production.We were keen to prove it, and we continue to do it.The concept of solidarity has taken on its full meaning, and I thank again all the people who followed us in this adventure.Like an interconnected sector, everyone needs the other, it is strictly impossible to do alone.

Denim made in France is gaining momentum, can we speak of healthy competition?

With Thomas Huiez (1083), Julien Toffery (Toffery workshop) or Clément Pradal (vintage Kiplay), I think I can say that we know each other well and that we exchange regularly. We are finally all at major stages of development of our businesses. No one can say if one day one of us will be more important on the market, especially since others still arrive such as the Mulliez group with its jeans factory project in the north of France . That this major industrial group can be interested in French manufacturing, even if we expect more information, particularly on the process and the final price of their jeans, gives even more legitimacy to projects made in France, of a more fashion transparent that we have been leading for several years with the colleagues mentioned above. It is up to us to demonstrate in a even more educational way what a jeans "fabricated otherwise". And let's not forget that at the base, fashion is made to have fun! We will have to find this right balance between guaranteeing transparency, developing our artisanal know-how, and continuing to offer beautiful fashion products.

On the communication side, you work as a "native digital" brand with an online store, an presence on social networks, web series, videos around hand intelligence ... Is it essential to reach the end customer?

It is essential, even if today we remain a more "confidential" brand than some of our colleagues.So far we have chosen not to be accompanied by the communication strategy, but it is perhaps also just a question of opportunity that has not presented itself!Until now, our customers have known us above all by word of mouth and via our network of partners, but they quickly become followers on the networks, and are very committed to their purchases.

Romain and I have the experience of ready-to-wear, retail and manufacturing, and I believe that we are really aware of the importance of merchandising, how to present our clothes, storytelling.This participates in the brand image, on networks but also in stores or at the annual Made in France (MIF Expo) fair.

You have just communicated on the new roadmap for DAO, what are the outlines?

In 2018, I set up a roadmap called Alternative 2022 manufacturing, which will soon end.So we had to set new goals and communicate them.We will of course continue to strengthen our manufacturing capacities in France, with always 100% of the making in France, but with a desire to find new weavers to reach 80% of woven tissues in the territory from 2022, the remaining 20%being woven in Europe.As evoked, we will strengthen the traceability of materials with more audits among our suppliers. Finally, in matters of social responsibility, we must always guarantee the equality of wages men-women, promote people on positions of responsibility.For example, we have just appointed workshop manager one of our seamstresses, only 26 years old.It was obvious, the future will undoubtedly confirm the relevance of this decision.

Personally, do you have a favorite brand?

Kilomet109 is a brand of Vietnamese origin which manufactures clothes thanks to completely transparent methods, because from cotton cultivation, weaving on a manual shuttle business, passing through the vegetable dye of clothes to the manufacturing everything happens in theNorth of Vietnam near Hanoi, or in remote villages in the same region.Seen Thao (the founder) perfectly masters her value chain and really highlights artisanal know-how to develop short circuit clothes, completely transparent, demonstrating at the same time that Vietnam is not just one of the“Atelier du Monde” country but can also be an example in responsible fashion.

Interview by N.RIGHI - December 2021

Related Articles